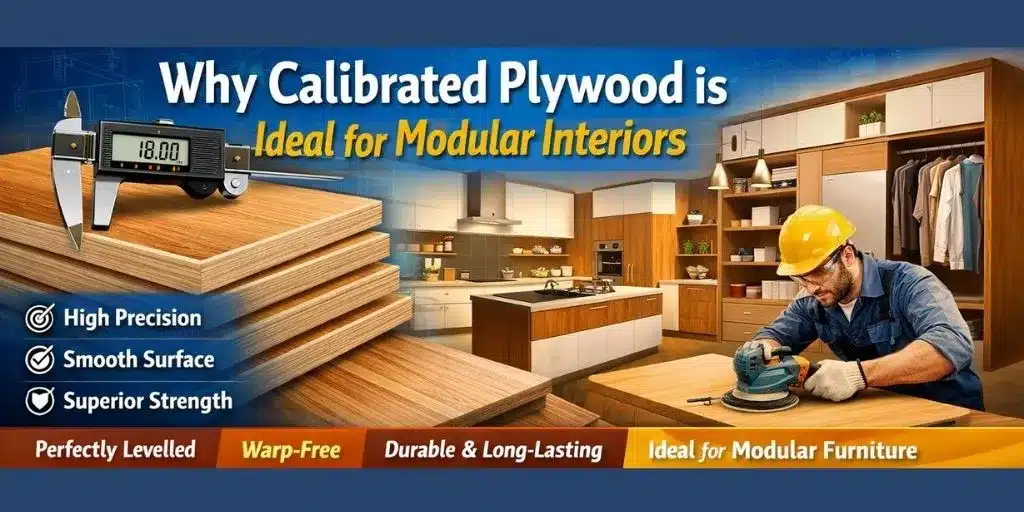

We know how diverse the world of plywood is. From shuttering plywood in construction to fire-retardant ply in commercial complexes, the engineering innovations and variety of wood offer great flexibility in designing. In modern interiors, consistency is the non-negotiable. Whether it is a kitchen cabinet or a bed in the living room, every sheet of plywood needs to be in uniform dimensions, grain, colour, etc. Non-calibrated plywood may have the desired qualities you expect from your plywood sheets, but without calibration, you cannot be sure. A calibrated plywood supplier is in high demand by interior designers, architects and homeowners today. By ensuring calibration, the supplier provides many benefits for the users.

Understanding the Calibration Process

Plywood is an engineered wood, as it is prepared by layering together veneers. A good calibrated plywood supplier uses top-grade materials, machining processes, resins, and adds preservatives for durability. However, there are certain inaccuracies still left despite precision engineering processes being followed. Thickness may be tapered, or the surface may contain voids or bumps. In such cases, a calibration process is used. This process is not just an addition but an advancement in basic processes. It begins at the core veneer pressing stage, where the veneers are evenly pressed under high temperature and pressure conditions. And then after all treatments are done, it goes into a sanding machine where a super smooth surface and precise dimensions are achieved.

Top Benefits of Calibrated Plywood

Faster Installation

Irregular plywood can lead to many issues, and misalignment is one of them. Even minor misalignment can poorly affect the shutter fitting and hardware installation in the kitchen cabinets, wardrobes, and storage racks. This allows carpenters to work with exact measurements and minimize the risk of reworking.

Better Surface for Finishing

The stable surface by a calibrated plywood supplier helps in applying the laminates or veneers. It forms an even base without voids and bumps, avoiding the risk of bubble formation, ridges, uneven bonding and poor quality finishing.

Compatibility with Modern Hardware

Modern interiors have soft-close hinges, concealed channels and hardware. These need precise clearance to fit perfectly into the doors and drawers. With calibrated plywood, the hinges align properly and drawers close smoothly. They are compatible with modern hardware and ensure quicker installation and fitting.

Dimensional Stability

Good quality calibrated plywood has dimensional stability, which makes it last longer with the joints and hinges. It prevents sagging or loose shutters of the interior furniture, fixtures and panels. Stable dimensions also avoid jamming of the locks of doors, as misalignment often results in locking failure.

Conclusion

Modern interiors feature elements that are constructed with fine and elegant looks and serve their function for a long period. Therefore, most homeowners and architects prefer a calibrated plywood supplier for their various woodworks. It helps with quicker installation, stable dimensions, and reliable finishing. If you want to buy from a trusted supplier, choose Kridha Laminates. We double calibrate our plywood to ensure ultra-precision outcomes.